Error de formato de correo electrónico

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

Enhancing Plastic Performance: Exploring Methods of Plastic Modification

Plastic modification, a crucial process in the manufacturing industry, aims to enhance the properties of plastics to meet diverse application requirements. As a leading manufacturer of modified plastic pellets, TOPONEW specializes in employing various methods to tailor plastics to specific needs.

Introduction: Plastic modification involves incorporating additives or altering the chemical structure to improve performance and extend the scope of applications. At TOPONEW, we employ a range of techniques to achieve desired outcomes, ensuring our customers receive high-quality modified plastic pellets that meet their exact specifications.

Methods of Plastic Modification:

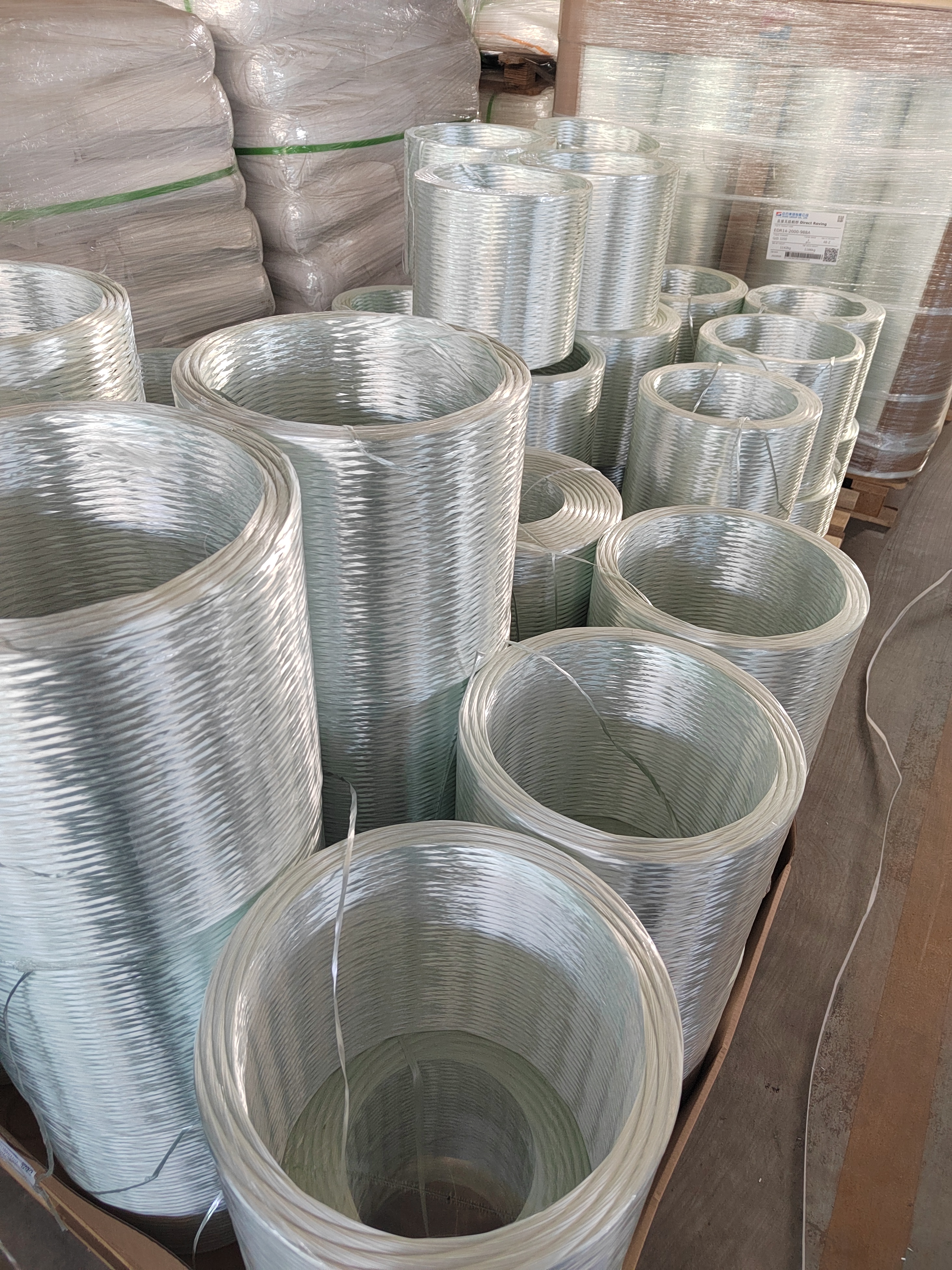

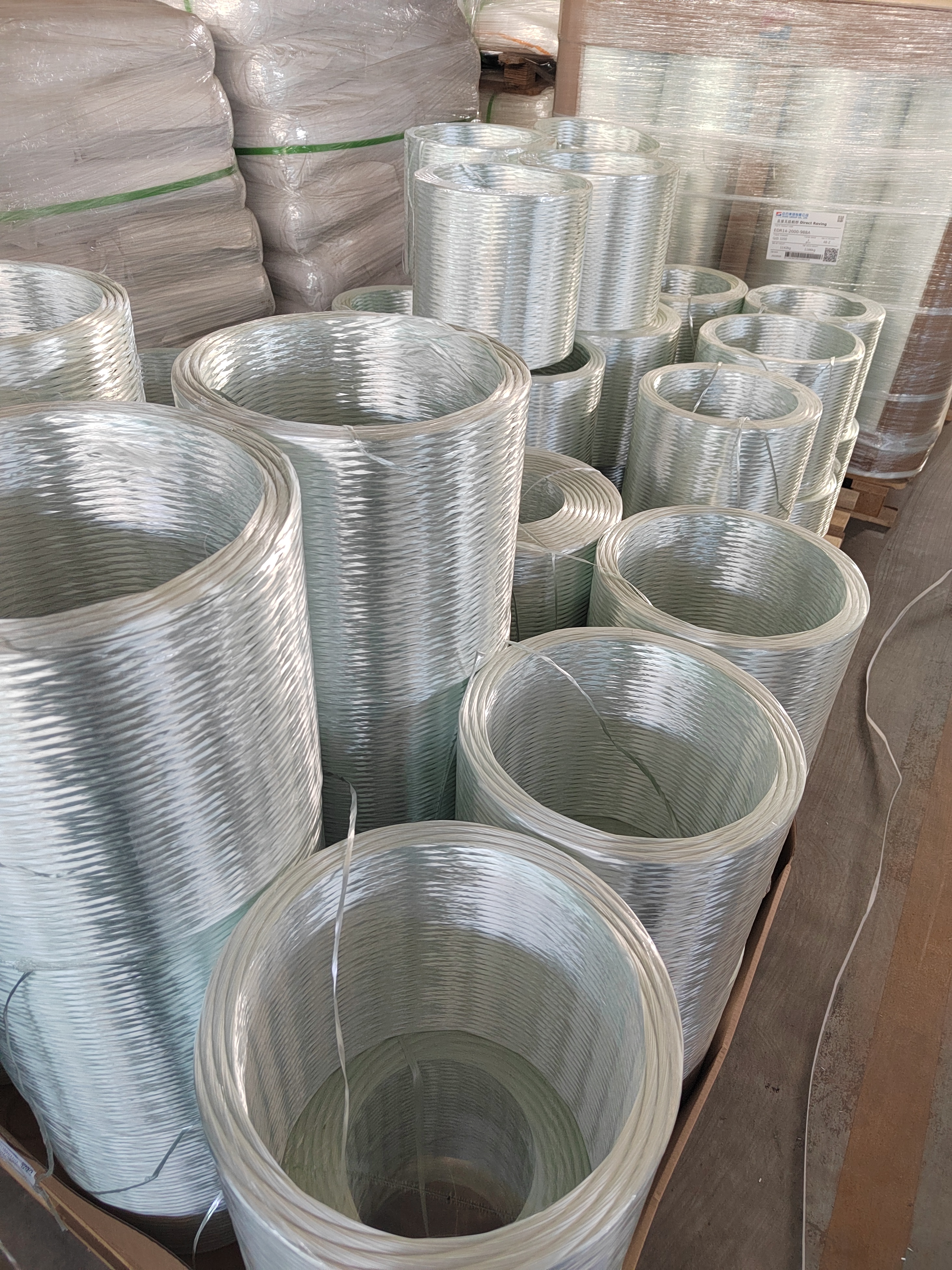

Reinforcement: One of the primary methods is reinforcement, where materials such as glass fibers, carbon fibers, or mica powder are added to enhance the rigidity and strength of plastics. This method is commonly used in applications requiring high durability, such as automotive components and industrial tools.

Glass fiber

Toughening: To improve toughness and impact resistance, additives like rubber or thermoplastic elastomers are introduced into the plastic matrix. This enhances the material's ability to withstand sudden shocks, making it ideal for products like automotive bumpers and household appliances.

Blending: Blending involves mixing two or more polymers to create a homogeneous blend with improved properties. By carefully adjusting the composition, we can achieve the desired balance of mechanical, optical, and processing characteristics, catering to a wide range of applications.

Alloying: Similar to blending, alloying combines compatible polymers to form alloys with enhanced performance. These alloys offer unique properties that individual components cannot achieve alone. For instance, PC/ABS alloys exhibit exceptional strength and heat resistance, making them suitable for demanding applications.

Fillers: Fillers, such as inorganic minerals or organic fibers, are added to plastics to improve mechanical properties and reduce costs. Common fillers include calcium carbonate, silica, and wood fibers, which enhance stiffness and reduce material expenses.

Other Modifications: Beyond the aforementioned methods, plastics can be modified through various means. This includes incorporating conductive fillers to reduce electrical resistance, adding antioxidants or UV stabilizers to enhance weather resistance, and introducing pigments or dyes to alter color. Additionally, lubricants can be used to improve processing, while nucleating agents alter crystalline properties for improved mechanical and optical performance.

Conclusion:

In conclusion, plastic modification is a multifaceted process that involves a range of techniques to enhance material properties. At TOPONEW, we leverage these methods to produce high-quality modified plastic pellets tailored to meet the diverse needs of our customers. With our expertise and commitment to innovation, we continue to push the boundaries of plastic modification, driving advancements across various industries.