Error de formato de correo electrónico

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

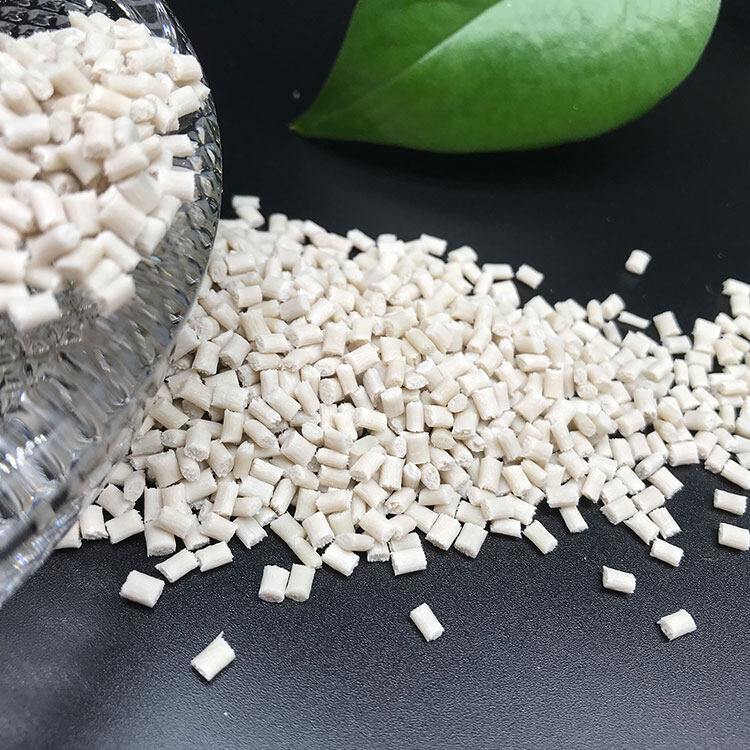

Navigating the PPA Granules Supply Chain: A Comprehensive Guide

Introduction:

Welcome to TOPONEW, a renowned manufacturer of modified PPA plastic granules. In this comprehensive guide, we will delve into the intricate world of PPA granules supply chain management. Whether you are new to sourcing PPA pellets or looking to optimize your existing supply chain, we will provide valuable insights and strategies. Let's explore the key aspects of the PPA granules supply chain process.

-

Understanding the PPA Granules Supply Chain:

The PPA granules supply chain encompasses the entire lifecycle of procuring, manufacturing, and delivering PPA pellets to your desired location. This process involves multiple stakeholders, including manufacturers like TOPONEW, suppliers, distributors, and end-users. -

Assessing Your PPA Granules Requirements:

Before proceeding, evaluate your specific PPA granules requirements. Consider factors such as application requirements, required material properties, quantity, timeline, and desired quality standards. Understanding these requirements will help you align your supply chain strategy accordingly. -

Identifying Reliable PPA Granules Outsourcing Options:

Outsourcing PPA granules production offers various benefits, including cost-effectiveness, specialized expertise, and streamlined operations. While sourcing, consider partnering with established PPA granules agencies or manufacturers like TOPONEW. Look for companies with a proven track record, expertise in PPA granules production, and a commitment to quality. -

Establishing Robust Supplier Networks:

Building a strong network of PPA granules suppliers is paramount to maintaining a smooth and uninterrupted supply chain. Engage with multiple suppliers to mitigate risks associated with dependence on a single source. Conduct thorough due diligence, scrutinize supplier capabilities, certifications, and compliance with industry standards. -

Streamlining Logistics and Distribution Channels:

Efficient logistics and distribution channels are essential for timely delivery of PPA granules. Collaborate with experienced shipping companies or logistic partners with a strong understanding of handling plastic granules. Optimize transportation routes, consider factors like cost, transportation modes, and delivery timelines to establish seamless supply chain operations. -

Ensuring Quality Control and Inspection:

Quality control plays a pivotal role in maintaining high product standards. Collaborate with suppliers that abide by stringent quality control practices, have well-established testing procedures, and adhere to industry standards. Regularly conduct inspections and audits to ensure consistent quality throughout the supply chain.

Conclusion:

Effectively managing the PPA granules supply chain is crucial to meet your manufacturing requirements. By understanding the various aspects of the supply chain process, identifying reliable outsourcing options, establishing strong supplier networks, streamlining logistics, and prioritizing quality control, you can optimize your PPA granules procurement. TOPONEW, as a reputable PPA granules manufacturer, is dedicated to delivering high-quality products and exceptional customer service. Reach out to us today to experience a seamless and reliable PPA granules supply chain partnership.

https://www.toponew.com/products/ppa-compound/PPAGF50-TPA380G10HS