Error de formato de correo electrónico

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

resetAccountPassword

forTheAccount

pwdLetterLimtTip

inconsistentPwd

resetSuccess

resetSuccessTips

login

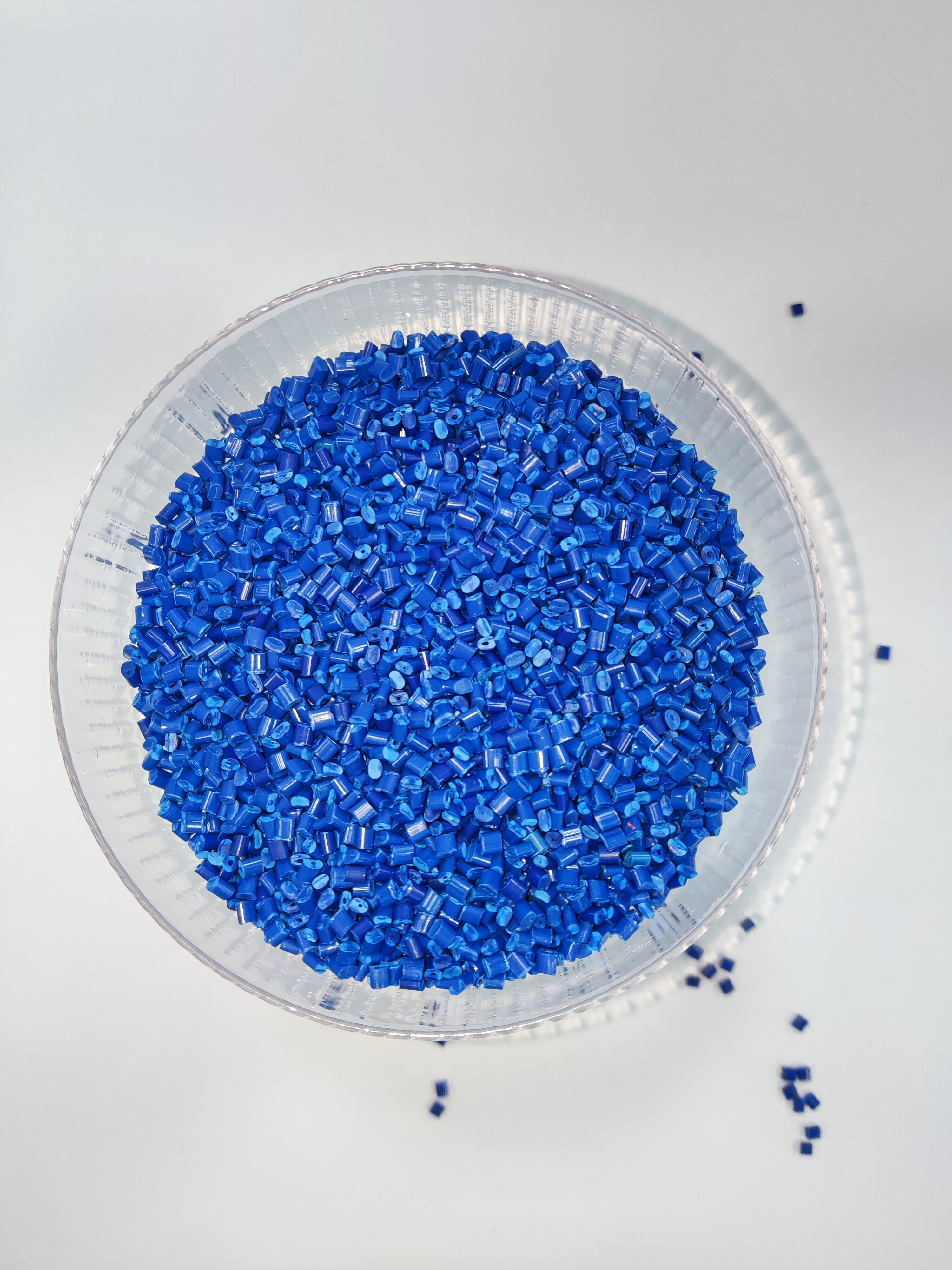

ABS A07C30BK

ABS A07C30BK

Carbon Filled: 30%

(Custom materials available according to your Technical Data Sheet)

Contáctenos

Inquiry Basket

Código de producto:

ABS A07C30BK

OEM:

Disponible

Muestra:

Disponible

Pago:

T/T

Lugar de origen:

China

Transporte:

Sea freight · Land freight · Air freight

Capacidad de suministro:

3000 ton por Mes

Contáctenos

ETIQUETAS DE PRODUCTOS